Water treatment project in accordance with AWWA C209 and AWWA C214

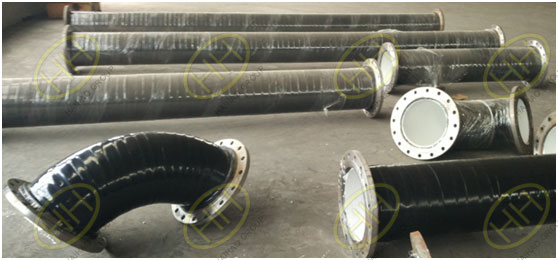

Haihao Group is attending a water supply pipelines project in recent; the products are pipe spools and flanges. According to technical documents requirement, the coating is in accordance with AWWA C209 and AWWA C214.

AWWA C209 and AWWA C214 are both tape coating standards, which are applied to exterior coating of underground steel water pipelines. Why there are two standards? Which standard should we follow?

AWWA C209 – Cold-applied tape coatings for the exterior of Special Sections, Connections and fittings for steel water pipelines

AWWA C214 – tape coating systems for the exterior of steel water pipelines

From the title, we can know that they are used for different components of pipeline.

Regarding this project,

If the pipe spools consist of pipe and flange, the coating will be accordance with AWWA C214.

If the pipe spools consist of fittings, the coating will be accordance with AWWA C209.

Is it the only difference? NO! There are many differences as following:

| Coating system | Liquid adhesive | Tape | total minimum Thickness | |

| AWWA C209 | Liquid adhesive +prefabricated tape | Liquid adhesive could be applied without heat | the tape consisting of a laminate composed of a plastic film backing and a homogeneous bituminous-sealant or elastomeric-sealant layer | 750μm |

| AWWA C214 | Liquid adhesive +inner layer-tape+ outer-layer tape | Liquid adhesive is solvent based or 100% solids (it needs heat) | the tape is a two-layer tape consisting of a polyolefin backing layer with a laminated butyl adhesive layer | 1.17mm or 1.85mm |

How about the preparation of pipeline?

They are same; the surface of pipeline is in accordance with SSPC-SP6/NACE No.3.