Haihao Group are attending water treatment project in Vietnam

Haihao Group are attending water project in Vietnam in recent, the products are pipe spools, flanges, puddle pipes. The internal coatings are liquid epoxy; the external coatings are tape coating.

Liquid-epoxy coatings are very regular coatings for steel water pipeline, which is in accordance with AWWA C210 -15 – standard for liquid-Epoxy coatings and linings for steel water pipe and fittings. The requirement of surface is SSPC-SP 10/NACE No.2.The minimum dry film thickness (DFT) is 406μm.

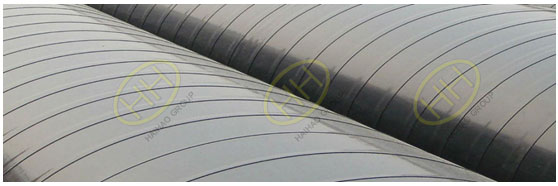

Tape coatings are mainly used for external coatings of underground pipeline or underwater, which is according to AWWA C214 –Tape coating systems for the exterior of steel water pipelines.

The requirement of pipe surface is in accordance with SSPC-SP6/NACE No.3.The weld seams shall be ground flush for a distance of 18in. (450mm) along the length of pipe on both ends.

Tape coatings system has at least three layers consisting of the following:

- A solvent-based or 100% solid –liquid adhesive layer.

- An inner-layer tape for corrosion prevention.

- An outer-layer tape for mechanical protection.

Regarding thickness:

The minimum thickness of inner-layer tape is 0.48mm

The minimum thickness of outer-layer tape is 0.724mm

The total thickness is two choices:

Normal thickness: 50 mil (1.27mm); minimum thickness: 46mil (1.17mm)

Normal thickness: 80 mil (2.03mm); minimum thickness: 73mil (1.85mm)

Why there are two “total thickness”?

80mil (2.03mm) is suggested for pipe diameters greater than 54in. (DN1400mm).The purchaser or manufacturer may recommend this thickness.

50mil system can be used for all pipe diameters with the application of a manufacturer-approved rock shield.

Haihao Group is very familiar with AWWA standards and has much experience in fabricating pipe spools. Our engineers are ready to offer best solution for this project.